Location: Faringdon, Oxfordshire

Services used:

Materials Used:

Problem: This aim of this particular project was to restore a fireplace that had been altered over the years which reduced its size and removed some of its original features. To achieve this, we would need to open up the fireplace and remove a brick course at the rear and front of the opening. This would then create enough space to accommodate a newly installed log burner. Period properties that have open fires that were used in most cases to heat homes or even for cooking, tend to suffer from salt damp. Salt damp is an extremely common damp problem on chimney breasts and fireplaces. This occurs because fossil fuels such as coal hold natural salts from the ground that migrate into the fabric of the building. These salts are usually sulphate and nitrates that cause damp by absorbing moisture from the atmosphere and tend to be more prominent in environments with high humidity. The build-up of these ground salts can cause staining and even cause blown plaster with salts visible on the wall surfaces. Once these salts migrate into the fabric of a building, they can never be fully removed so specialist damp proofing is essential and in this case study we used a damp proof membrane to isolate the newly installed plastering from contact with the contaminated wall. Lime render was used inside the fireplace opening to provide a more historic, aesthetic look that the client wanted.

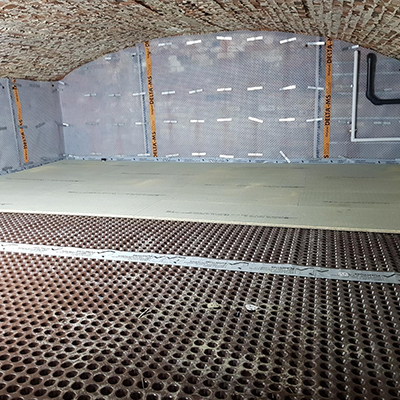

Works completed: We firstly covered the work areas with polythene sheeting and floor protection prior to our technicians commencing work. This is a priority for all projects we work on. The contaminated wall plaster was then carefully removed, exposing the brick face behind, ready for the mesh coated membrane and dry lining system to be fixed in place. A specialist render was then applied to the outside of fireplace ready for plastering and new skirting boards to be installed.

The fireplace opening was then cleaned and prepared for the two coats of hydrated lime plaster, leaving the new space ready for the installation of a new log burner.