Location: Newbury, Berkshire

Services used:

Materials Used:

Problem: Occasionally, we see fundamental flaws in the design of a building project. For this tanking project in particular, these design flaws led to extensive problems relating to the build up of water. When this newly constructed property was built, the main considerations that were overlooked were the lack of drainage for rain water and the water table itself. The water table refers to the upper surface of the zone of saturation where pores and fractures of the ground are saturated with water. It can be simply explained as the depth below which the ground is saturated. This property was built on a plot of earth which contains a high level of clay and at the base of a gradual slope. This caused rain water to run towards the property beneath the soil, allowing water to enter the building. Our CSSW certified surveyors have vast amounts of experience working on new build construction projects, both before and during the building phase. Our tanking surveyors proposed changes to the below ground external drainage which was undertaken by contractors on the instruction of Property Conservation Services. The aim of these proposed changes was to prevent surface water build up. Once these changes were completed and the external water build up was effectively managed, our attention turned to sealing the floors within the property with a tanking system. This involved using a crystalline tanking slurry and rubberised liquid membrane to prevent ground water from building up.

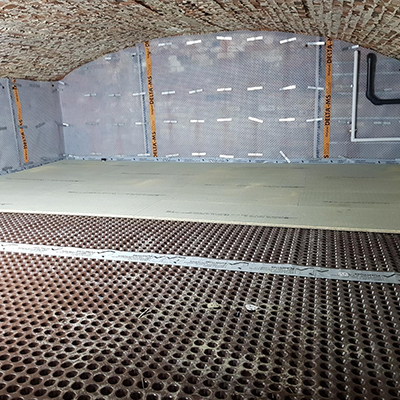

Works completed: The first stage of this tanking project involved the excavation of the perimeter of the property and the installation of a land drain which is designed to collect ground water and direct this water into existing drains. ACO drains where then installed adjacent the external floor wall junction. These drains also direct water into existing drainage. This then completed the water management of ground water penetration. Our tanking experts then cleaning all of the internal floors of the property with high powered power washers, ready for the application of tanking products. Once this initial drying process had finished a second coat of Koster 21 was applied with a mesh for strength between adjoining slab surfaces. The final drying process of Koster 21 completed the installation of the internal tanking system, creating a fully bonded system to prevent water ingress.

Koster repair mortar was then applied to the floor wall junctions to seal any gaps. Koster NB1 crystalline slurry was applied to the walls and an even coat was applied to all floors within the property.